Digital Doppelgangers in agrifood

What are digital twins and why are they hard to pull off?

In person event in the San Francisco Bay Area: If you are going to be in the San Francisco Bay Area, I would love to invite you to a free evening event on Sept 30th, 2024.

I have teamed up with Walt Duflock (Western Growers Association), and Sachi Desai (Bayer Crop Science) to organize an informal meetup called “AgTech Alchemy”. The goal is to meet other agrifood practitioners, researchers, and enthusiasts in an informal setting. You can register here for free.

Thanks for reading Software is Feeding the World! Subscribe for free to receive new posts and support my work.

–

Digital Twins

In the pandemic era FX series “Devs”, starring Nick Offerman, software tech giant Amaya believes it has built powerful software which can play back and visualize the past, and then use huge amounts of data to predict the future. They believe they have built a massive simulation engine and a digital twin of reality. Devs take in data about causes and effects and somehow map this data backwards and forwards.

A digital twin is a fairly new concept. It was first anticipated by computer scientist David Gelertner in his 1991 book, “Mirror Worlds.” Michael Grieves popularized the concept of “digital twins” in the early 2000s. When it comes to food and agriculture, digital twins are a recent phenomenon.

Digital twins have been much more extensively adopted in more controlled environments like automation and manufacturing.

Due to the complexity of nature based systems in open-field environments, they have been slow to come to agriculture.

Digital Twins are virtual, digital equivalents of physical objects. They are real-time and remotely connected to real objects and provide rich representations of these objects and its context.

Digital twins are detailed models of factories and processes which mirror their inputs, functions and outputs with a high level of accuracy. Thus, they can predict the effects of certain changes and offer a valuable opportunity to tinker with different variables, with the advantage of being in ‘sandbox’ mode.

Once a digital twin is validated as running realistically, the model follows the laws of physics, chemistry and biology to model what happens when circumstances change.

A field is a factory to grow crops. There are many different processes which have an impact on how the crop grows throughout the season. If we can create a digital twin of the field, then fields could be managed in a more effective and predictable fashion.

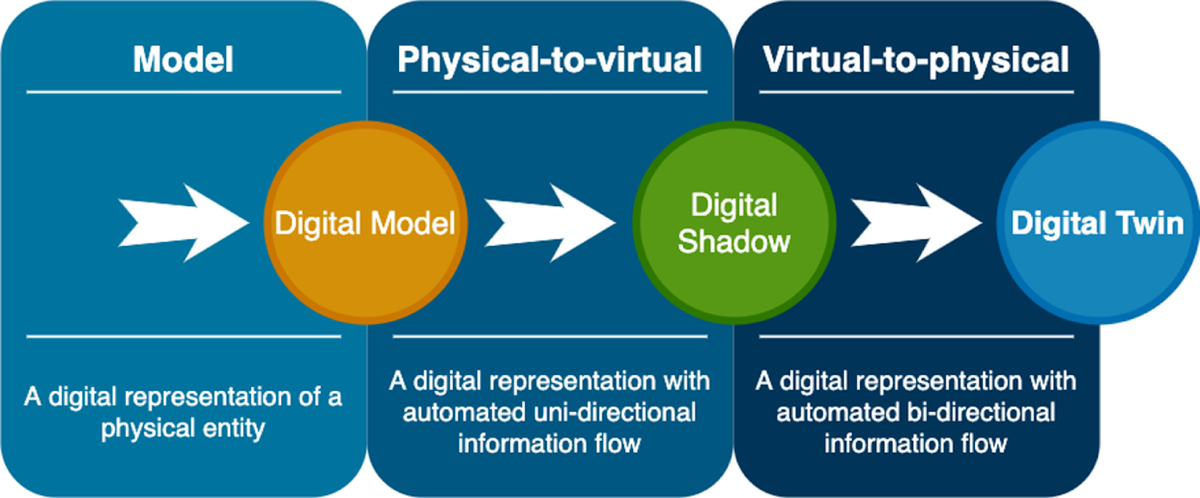

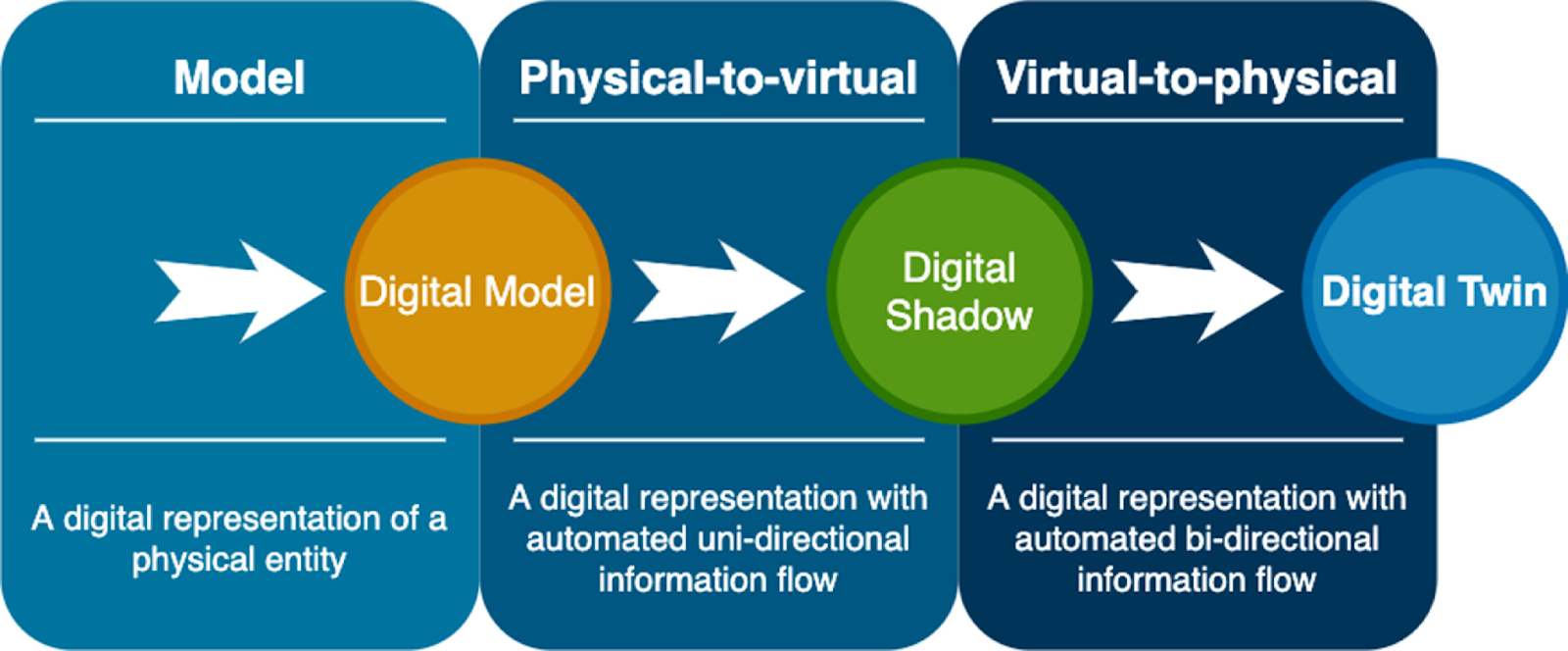

The process of digital twins begins with creating a digital representation of a physical entity (called a model). This is quite common and well known in agriculture. All of us have heard about different process models like crop models, APSIM, DSSAT etc. are examples of models which try to understand the physics, chemistry, biology etc. of natural and crop cycles, and help to explain and predict real life behavior.

These models take a physical process and represent it virtually. Digital twins take it further and enable a digital representation with bi-directional information flow between real life and its digital representation and vice versa.

Within agriculture, the process to take lab-based soil sampling, field scouting, are traditional methods to understand and characterize on the ground (and under the ground) conditions. These methods are time-consuming, expensive, and are limited in scope, accuracy, and scalability. The use of digital twins allows for a holistic and continuous assessment, which can lead to better decisions.

For a digital twin to serve as a precise counterpart for a real-world object, it requires sufficient data. Digital twins rely on pervasive real-time data collection from various sources, including satellites, drones, embedded sensors, and RFID tags, as well as historical information on soil management, planned crops, and weather patterns.

By analyzing consolidated data from a single digital twin platform, farmers can foresee potential deviations, simulate effects of interventions, and effectively respond to possible issues (or prevent them altogether). All these measures can be taken remotely, without the need for immediate on-site examination.

With digital twins, you get a continuous monitoring and reporting system that alerts you of pest-affected plants, a cow’s poor health, an equipment malfunction, soil dryness, or a temperature drop. Digital twins are also a powerful simulation and prediction tool to envision the impact of farming practices and the forces of nature on your business and prepare for possible scenarios.”

Here are some examples of digital twins in agriculture,

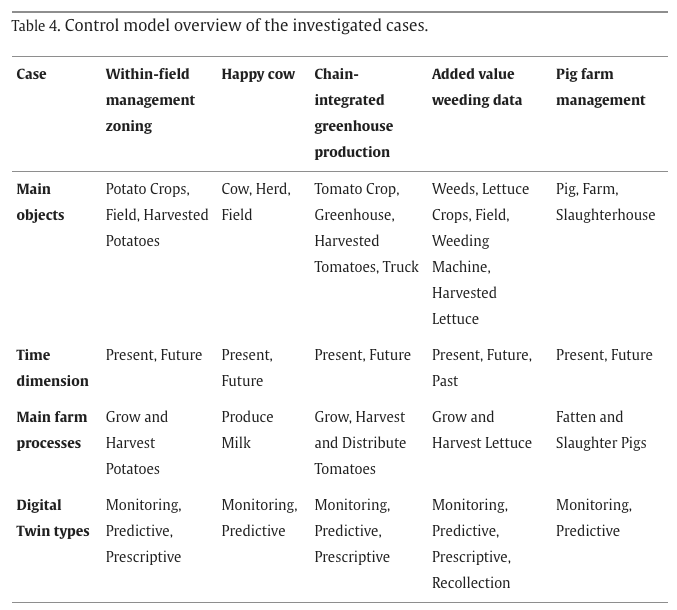

Image source: Cor Verdouw, Bedir Tekinerdogan, Adrie Beulens, Sjaak Wolfert, Digital twins in smart farming, Agricultural Systems, Volume 189, 2021, 103046, ISSN 0308-521X, https://doi.org/10.1016/j.agsy.2020.103046

LandScan’s Digital Twin Patent

Landscan.ai was recently granted a digital twin patent focused on modeling soil characteristics. LandScan typically works with specialty and tree crops. Some of the key features of the patent are high resolution data analysis using data from multiple sources predictive modeling by stimulating different management practices, dynamic adaptation based on changing conditions, integration with precision farming tools and sustainability and resource management.

One of the key threads for the patent is a digital twin of soil. Soil properties are one of the hardest to measure, monitor, and scale accurately. Due to the expense involved with soil sampling (and also the slow rate of change in soil properties), soil samples are typically taken once every few years.

There are many modeling approaches to reduce the number of soil samples, and to characterize certain soil characteristics like soil organic carbon, or nitrogen recommendations by using process models.

LandScan uses proximal soil sensors which use a Digital Soil Core probe with different sensors to measure soil properties and create a digital ground truth data signature for different fields.

The Digital Soil Core (DSC) is a probe with 7 independent sensors that is pushed into the ground at a continuous rate that enables the DSC to characterize the full soil profile to a depth of 120cm+ in about 1 minute. The DSC is part of the LandScan Platform for Discovery site characterization and analysis system where it is digitally synchronized with other complementary technologies.

The initial measurements are used to characterize the agricultural site. This data is used to understand the most relevant locations to place IoT sensors, and monitor dynamic field characteristics.

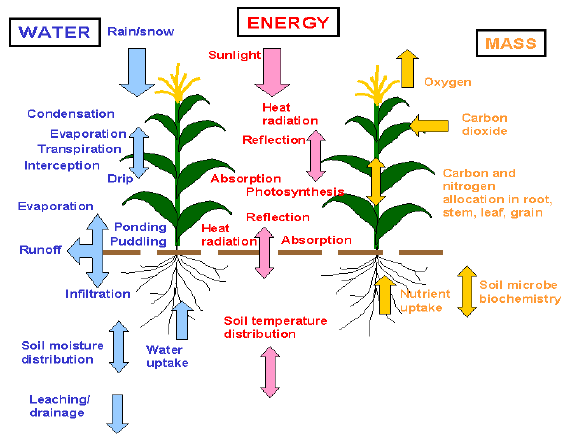

LandScan takes in all this real time data and feeds it to a biophysical model called PALMS, which incorporates water, energy, and mass balance of a cropping system (PALMS was developed by Dr. John Norman from the University of Wisconsin-Madison).

PALMS is a ‘model of models’ for precision irrigation, fertility, and management and also provides a framework for LandScan analytics. LandScan has a license from the Wisconsin Alumni Research Foundation (WARF); it was previously licensed by John Deere and Trimble.

Image Source: PALMS model Source LandScan.AI website

The continuous flow of data from in-ground sensors is used to constantly evaluate and calibrate the performance of the PALMS model. This creates a digital twin of the site and the crop growing in that field, which is informed by a two directional data flow between the real world sensors, and the digital twin.

OFI (Olam Food Ingredients) and Mars have been reported to be working with LandScan’s digital twin capability, but it is not clear how they are using it. In the case of Mars, I am guessing it is being used to model and report on soil sustainability metrics like organic carbon, soil erosion, microbial activity etc.

Mars is excited to begin working with LandScan’s digital twin technology for the purpose of optimizing international cocoa production and providing important soil health sustainability metrics for our supply chain.

The challenges with digital twins

Digital twins are extremely hard to build, maintain, and operate in an effective manner, especially for an open system like agriculture, which is dependent on environmental factors like weather, rainfall, soil characteristics, the genetic potential of seeds, and the impact of management practices. Due to the uncertainty in all these variables, it is very difficult to build digital twins within agriculture.

Digital twins have to rely on large amounts of real time, high quality data. Collection of high quality data is expensive and difficult in complex environments. Low cost IoT devices which can capture important and relevant data, and make it available to the model are a key requirement for creating digital twins in agriculture. This problem is further compounded in the case of agriculture as many farms are in remote areas with limited connectivity.

Digital twins require the integration of multiple systems, sensors, and connectivity between sources of data. The lack of integration between these components can make the data collection, transmission, storage, and analysis of data difficult. It causes your digital twin to drift from reality, and it is no longer a digital doppelganger of reality, leading to suboptimal or incorrect decisions.

Scaling digital twins is a big challenge. If your digital twins rely on efficient operation of sensors, the scaling of your digital twin is heavily dependent on the cost and scalability of your sensor network. It can make the development of a digital twin very expensive, and will easily crowd out smaller operations. Agriculture is a biological system. It is highly dependent on uncontrolled factors such as weather, pest, disease, and are different across different locations.

This is one of the biggest challenges to scale digital twins. Agriculture is a multidisciplinary field, which integrates knowledge from different fields. It can be important to understand the impact of these factors and their interaction to build an accurate digital twin model.

An intermediate approach to building digital twins for whole systems, is to model smaller subsystems with a fewer number of variables. These in-silico representations of subsystems are not a digital twin for the entire system, but it can be a good way to understand specific aspects of a particular process, its dependencies, and its interaction with other parts of the system. These digital mini-twins can also be used to stress-test certain aspects of the subsystem and get a better sense of inflection points in system behavior.

LandScan’s patent is a good start and a realization of the potential power of digital twins, but we still have a long way to go to have effective digital twins in an open system like agriculture. The

Digital twins definitely have applicability throughout the food and agriculture supply chain, including processing, transportation and logistics, traceability, ingredient formulation, and ultimately the holiest of grails in agriculture - understanding the G x E x M equation.

Thanks for reading Software is Feeding the World! Subscribe for free to receive new posts and support my work.