AI for Food Inspections and Food Waste Management

Use of AI and analytics in the produce supply chain

Welcome to the June 1, 2025 edition of SFTW.

MDL & AA Happenings

- Metal Dog Labs released part 2 of the GenAI in Ag report. The second part focused on Value Creation Frameworks, and provides a playbook on how to think about and execute on GenAI based projects. Both the reports are available for free to SFTW members. You can get your free copy here by Signing In (for existing subscribers) or by Signing Up (for new subscribers).

- AgTech Alchemy will host two events on the same day in California and in Fargo on June 12th. Do not forget to register, if you plan to attend one of the events.

- SFTW Convos will return on Wednesday with a conversation with Guy Coleman, open source advocate and creator of the OpenWeedLocator for precision spraying of weeds.

The explosion of AI awareness in the popular domain due to ChatGPT has even Grandma asking to get her own ChatGPT account, though she might not know how to flip to the back camera while being on a video call with her grandchild.

But contrary to popular opinion, AI has been around for at least a few decades and the adoption of AI has accelerated over the last few years.

Over the next few weeks, I will bring you more and more examples of where AI is being used within the food and agriculture value chains, all the way from the consumer to farm, and everything in between.

If you are an enterprise in any industry, you cannot be sitting on the sidelines, when it comes to the use of AI within your business.

Scaling Regen Ag Starts with Better Data

Farmers Edge is building the digital backbone for regenerative agriculture—designed to simplify Scope 3 reporting and deliver credible results, fast. With Managed Technology Services built for agribusiness, Farmers Edge connects real-time field data to your sustainability goals across every acre and every grower in your network. From in-season tracking to end-of-year proof, Farmers Edge makes regen ag measurable and manageable. If you're serious about scaling impact and reporting, this is the infrastructure that makes it possible.

AI for Food Inspections and Food Waste Management

The United States Government Accountability Office estimates that the government loses up to $521 billion annually due to fraud, based on an analysis of fiscal years 2018 to 2022. Tax fraud, check fraud and improper payments to contractors, in addition to improper payments under the Social Security and Medicare programs have become a massive drag on the government’s finances.

AI-powered fraud detection solutions provide higher detection accuracy by looking at the whole picture instead of individual transactions, catching fraud patterns that traditional methods might overlook. AI can also help reduce false positives, tapping into quality data to provide context about what constitutes a legitimate transaction.

The U.S. Treasury Department began using machine learning in late 2022 to analyze its trove of data and mitigate check fraud. The department estimated that AI helped officials prevent or recover more than $4 billion in fraud in fiscal year 2024.

–

In February, the FDA failed to share the findings of its investigation into an E.coli outbreak that sickened nearly 90 people last fall with the public, according to the Washington Post.

The United States imported $ 213 billion worth of agricultural products in 2024. The FDA oversees all food products except those regulated by the USDA. The USDA primarily regulates meat, poultry, and egg products, while the FDA handles everything else, including food products that contain animal protein as an ingredient.

Given the sheer volume of food imports, the FDA only inspects a small percentage—often less than 1%—of shipments entering the U.S. To maximize efficiency, the FDA targets high-risk food categories, such as seafood, ready-to-eat foods, and products with a history of contamination.

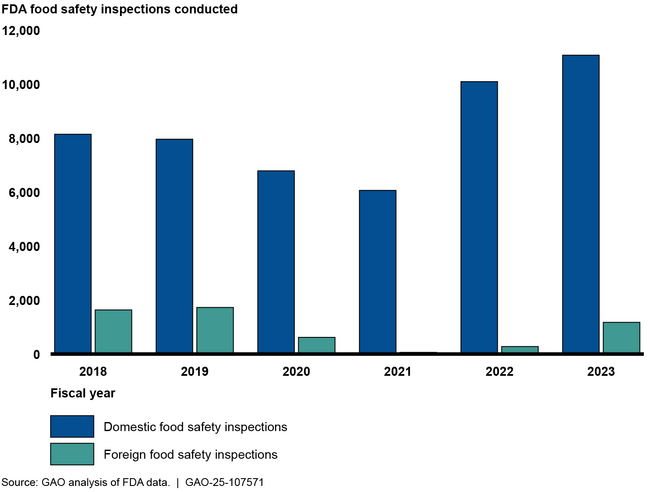

FDA has not met its domestic and foreign inspection targets since fiscal year 2018.

The FDA Food Safety Modernization Act (FSMA) directs FDA to inspect each high-risk domestic food facility at least once every 3 years and each non-high-risk facility at least once every 5 years.

For foreign facility inspections, FDA conducted far fewer than the annual target of 19,200 inspections identified by FSMA, according to FDA data. For example, the highest annual number FDA completed was in fiscal year 2019 when FDA inspected 1,727 foreign facilities—about 9 percent of the annual target.

It is no surprise that the FDA is now using artificial intelligence to help oversee the safety of the nation’s food supply. The FDA is using AI to identify where they should target their limited supply of food inspectors to go and inspect.

The FDA is focusing on seafood to help identify areas of high risk to be targeted for a closer look from a food safety and quality standpoint. The AI models are designed to improve the agency’s ability to quickly identify imported seafood products that may be contaminated by illness-causing pathogens, decomposition, the presence of unapproved antibiotic residues, or other hazards.

Machine learning gives the agency the ability to analyze data from various sources to help inform FDA decisions and target our resources at the borders. In a related shrimp pilot, we have begun to focus on areas of increased risk, such as shrimp contaminated by aquaculture drugs, for foreign inspections.

But what happens to certain food products before they are shipped post harvest, and once they are within the supply chain?

Spoilage within the supply chain

When I worked at HarvestMark (acquired by Trimble and now the technology is part of iFoodDS), we focused on collecting data on quality and freshness of fresh produce post harvest within the supply chain. We were collecting data on top for a traceability infrastructure, which could track produce at the lot level for not so high value crops or at an individual item level for high value crops like berries.

The idea behind the data collection was to understand what operational factors affected the quality and freshness of fresh produce as it moved through the supply chain to provide additional operational intelligence to the supply chain to make different decisions. One of the dirty secrets of fresh produce supply chains is the amount of food wastage which happens even before the product gets to the consumer’s kitchen.

This is typically called shrink within the grocery retail parlance. The industry has assumed it as a necessary evil for the longest time, though over the last 20 years people have started fighting back to see how they can run a supply chain with minimal shrinkage, while still providing a great product experience to the consumer.

Fungal decay remains one of the most persistent and complex challenges in the post-harvest supply chain. Once harvested, fresh produce loses its natural defenses and becomes highly susceptible to spoilage caused by fungi. These pathogens thrive in common storage and transit environments and can spread rapidly, making consistent and effective disease management essential. As produce moves through increasingly global and quality-driven supply chains, biological tools that can support freshness and reduce loss are becoming more important than ever.

An estimated 14% of fresh produce gets lost between harvest and retail. Much of this happens due to fungal infections that start once fruits and vegetables lose their natural defenses after harvest. The fungi thrive in storage and transport environments and can quickly spread if not controlled.

Fungicides are essential to protect fresh produce after harvest, especially for critical high-value and highly perishable crops, where even a small amount of waste can have large financial consequences.

AgroFresh and Biotalys announced a partnership last week to develop sustainable biological fungicide solutions.

Biotalys is bringing its AGROBODY™ platform to the table. This platform uses proteins to prevent fungal growth, offering an option for growers and distributors looking to avoid chemical residues. Biological fungicides based on strains like Bacillus and Trichoderma are showing good results in fighting decay. They support the preservation of quality during the often long journey from farm to market. The biological fungicide market for post-harvest use was valued at US$1.2 billion in 2024. It is expected to more than double by 2033, reaching US$2.5 billion. This growth is fueled by rising consumer awareness and increasing restrictions on chemical pesticides.

Based on supply chain infrastructure data, countries where the product is coming from, product characteristics, cold chain information, weather patterns, and other relevant factors AI can identify high risk products and shipments to inspect. Understanding how different products behave under different conditions paired with additional data and AI can help pinpoint problem areas more effectively.

AI in post harvest produce supply chains

During the AgTech Alchemy event in Seattle two weeks ago, we had a few startups present during the startup showcase. Two startups - Strella Biotech and Ripelocker are focused on managing post harvest supply chains for fresh produce. Both use a combination of a hardware solution, paired with analytics, predictive algorithms, and machine learning to solve a set of problems for post-harvest produce supply chains.

(Full disclosure: I DO NOT have any financial interest in Strella or Ripelocker)

Shipping perishables in RipeLockers suspends ripening and drastically reduces food loss during the transportation process. Because they are pallet-sized, portable, and stackable, they easily fit in many shipping configurations within the existing cold chain.

Ripelocker uses a controlled environment in the shipping container by creating a low pressure vacuum.

The vacuum works to slow the respiration and senescence of perishables stored inside. Maintaining low oxygen and pressure keeps them just above going anaerobic.

Image Source: Ripelocker website

Strella uses wireless sensors which track certain gases within packing houses and distribution centers, and combine them with advanced algorithms to help understand which produce pallets should be shipped first and where from their controlled atmosphere rooms to their customers. The prediction of produce maturity helps reduce waste, reduce the chances of shorting important customers, and make the right produce available to the right customer.

Strella helps to automate the ripening process of certain products like bananas and avocados. Bananas and avocados are ripened in a retailer’s distribution center till they are ready to be shipped to your local grocery store. This is a manual process today, typically managed by someone who has been doing that job for more than 30 years.

Image source: Strella Biotech website

Having visited multiple ripening rooms in my working career, it is very much considered an art form based on experience, rather than a scientific and data driven exercise. Small concentrations of ethylene gas are used in the ripening rooms for bananas and avocados to control the ripening process.

Strella solves it by using their hardware sensors, which can track certain gases and temperature within the ripening rooms, and use analytics to predict which palettes / cartons of bananas are ready to be shipped to the next stage (typically a grocery store).

Strella also helps to reduce shrink through inventory shipout management and real-time environmental monitoring for the produce supply chain.

It is important to see how data analytics, machine learning and AI is being used throughout the supply chain to solve gnarly problems which plague our food and agriculture systems.

There are a million problems to be solved, and if you can focus on customer pain points and the outcomes they expect, there is room for innovation and value creation within the industry.