Autonomy at CES

Deere and Kubota present autonomy solutions

Welcome to another edition of Software is Feeding the World. The CES was a big event in the world of Tech this past week, with many food and agriculture companies presenting at the show. Deere, Kubota, Driscolls, etc. were prominent examples. Today’s edition will talk about some of the announcements from Deere and Kubota.

Before we get into this week’s edition, I want to talk about an exciting new project I have been working on with Sachi Desai and Walt Duflock, under the AgTech Alchemy umbrella. We released the inaugural AgTech Alchemy Quarterly report last week.

AgTech Alchemy Quarterly

We're thrilled to introduce the inaugural AgTech Alchemy Quarterly, your go-to source for curated insights and expertise in the field. Inspired by the McKinsey Quarterly, our quarterly publication brings together handpicked articles, podcasts, and observations to foster learning and growth within the AgTech Alchemy community. Each issue is carefully crafted around a central theme, ensuring that you stay ahead of the curve in the rapidly evolving world of agricultural technology.

In this issue, our talented contributors dive into the complexities of success in AgTech, exploring what's worked, what's not, and what's on the horizon. They'll share their insights on the challenges and opportunities facing the industry and provide practical advice on how to navigate the landscape and make the most of the tools available. Join us on this exciting journey and discover the latest trends, breakthroughs, and best practices shaping the future of AgTech.

The first AgTech Alchemy Quarterly features fantastic writers and thought leaders like Janette Barnard (Prime Future), Walt Duflock (AgTech Alchemy & Western Growers), Ashley Sweeting (Ash Cloud), J. Matthew Pryor (Tenacious Ventures), Hollis Robbins (Anecdotal), Sachi Desai (AgTech Alchemy and Bayer), Ariel Patton (Topsoil), Shane Thomas (Upstream Ag Insights), Patrick Honcoop (AgTech Edge), Dan Schultz (Ag Done Different), Tim Hammerich (Future of Agriculture), and a small contribution from me as well.

You can download the free copy here. Do not forget to follow the AgTech Alchemy LinkedIn page for future events, and content.

We have started working on the Q1 issue and will be announcing the theme shortly.

-The AgTech Alchemy Team

Deere and Kubota talk autonomy

Noted political strategist, Peter Zeihan provides one view for the US Midwest. He imagines a future in which automated equipment with cameras will take photos of each individual plant. The equipment will identify if the plant is a weed, or a crop and assess the health of the crop. It will give it a little jolt of whatever is appropriate (herbicide, pesticide, fertilizer, water etc.). He believes we are on the verge of production increasing by a factor of 2-3 (“on the verge of” is subjective, though within the realm of possibility.) It will turn conventional farming into conventional gardening, with a lower pollution rating and a far lower carbon footprint. (Highlights by me)

–

Till a few years ago, the folks in AgTech didn’t pay much attention to CES for AgTech related news. Deere changed it all a few years ago by showing up with some of their cool toys. Deere has continued to do the same and this year was no different. It is a smart strategy to burnish their brand, attract future employees, and investors, and be part of the tech zeitgeist.

This year was no different.

John Deere revealed several new autonomous machines during a press conference at CES 2025 to support customers in agriculture, construction, and commercial landscaping. Building on Deere’s autonomous technology first revealed at CES 2022, the company’s second-generation autonomy kit combines advanced computer vision, AI, and cameras to help the machines navigate their environments. While each of these industries experiences their own set of challenges, a commonality across all is skilled labor availability. Agriculture: the American Farm Bureau Federation also estimates there are roughly 2.4 million farm jobs that need to be filled annually. Construction: Eighty-eight percent of contractors struggle to find skilled labor. Commercial Landscaping: 86% of landscaping business owners can’t find labor to fill open positions.

Both Deere and Kubota are able to find synergies across their construction, agriculture, and landscaping business to get leverage on the product development process. CTO of John Deere, Jahmy Hindman articulated these synergies and the common labor availability challenge across these sectors.

Our agriculture, construction, and commercial landscaping customers all have work that must get done at certain times of the day and year, yet there is not enough available and skilled labor to do the work. Autonomy can help address this challenge. That’s why we’re extending our technology stack to enable more machines to operate safely and autonomously in unique and complex environments. This will not only benefit our customers, but all of us who rely on them to provide the food, fuel, fiber, infrastructure, and landscaping care that we depend on every day.

Risk appetite and trust for autonomy

Depending on the cropping system, agricultural equipment performs different operations throughout the season. All of these operations are important, with planting and harvesting being the most important to the end outcome for commodity row crops.

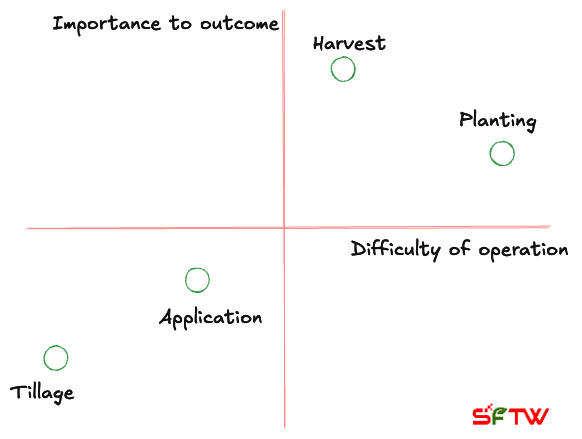

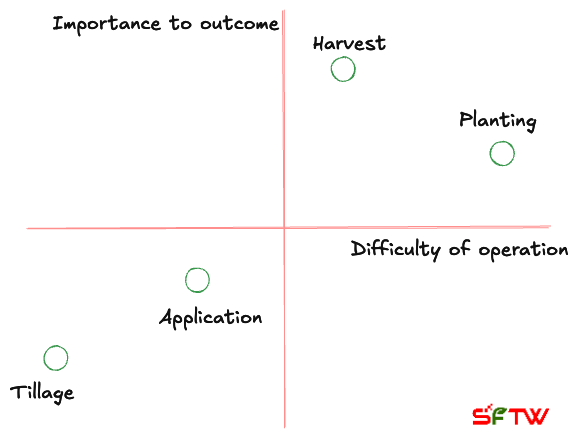

I have drawn a representative 2 x 2 diagram (commodity row crops) for how important an operation is to the end outcome of yield, and how difficult the operation is in terms of planning and actual execution. The relative position of the operations on the 2 x 2 matrix are empirical in nature and not to scale.

For example, tillage is an easier operation to do, compared to an application like broadcast spraying, which requires a higher degree of planning and execution compared to tillage.

Planting is fairly complicated for planning and execution (maybe even more complicated than harvest). In the case of commodity row crops, you have to think about past yield, soil characteristics, weed pressure in different parts of the field, which variety / hybrid to plant, when to plant, what should be the seed population etc.

Harvest is fairly important as it determines the final outcome of all the activities which have happened throughout the season.

When you talk with farmers, equipment dealers, and OEMs, they will tell you that when it comes to autonomy and automation, planting and harvest might be some of the last operations to be fully automated with a human in the cab. Casey Seymour, who has more than two decades of experience as an agriculture equipment dealer, and who is the creator of the Moving Iron podcast touched on trust and the importance of each operation.

It is going to take a long time for someone to feel comfortable enough to have a combine running in the field without anybody in it, and it's not throwing all the corn out the back of the combine.

For planting, you have to trust that the monitor is saying what it's saying, and you can see that. And then you trust that it's doing what it's doing.

And the third one is spraying. If you miss your mixture, you could burn up your crop. Those three things are going to be the last holdouts for anything that's autonomous.

Ground preparation with tillage, grain and crop handling are potentially the entry levels for autonomy.

Within commodity row crops, when it comes to automation, we see companies following the same sequence of operations to automate and bring autonomy to them. In the past, I have talked about autonomous grain cart operations, with a human operator doing other things or just monitoring it from a different location.

At CES, Deere talked about their autonomous 9RX tractor for large scale agriculture and tillage. With the second-generation autonomy kit, featuring 16 individual cameras arranged in pods to enable a 360-degree view of the field, farmers can step away from the machine and focus their time on other important jobs.

The advanced autonomy kit also calculates depth more accurately at larger distances, allowing the tractor to pull more equipment and drive faster.

In the case of tree crops, planting happens once every few years, though application happens multiple times throughout the year. Depending on the crop type, protecting crops through air blast spraying is a challenging and repetitive job, when it comes to fruits, nuts, and vegetables. The operation often involves driving up and down rows of trees, and often at night. The video below shows air-blast spraying of pecan trees.

As you can see, the operation is relatively straightforward and it is happening at low speed (2-3 miles per hour). But it can be exhausting and repetitive, when you think about multiple spray operations in a given season.

Deere already has GUSS sprayers in their portfolio, and it talked about the Autonomous 5ML Orchard Tractor for Air Blast Spraying. The autonomous 5ML orchard tractor addresses challenges with air blast spraying for pest control in high value crops such as fruits, nuts and vegetables.

It includes an autonomy kit with LIDAR sensors to address the dense canopies found in orchards. The LIDAR helps the GPS sense its surroundings using lasers to measure distance to enable better obstacle detection and navigation of terrain.

Following the work loop

Kubota is using the Work Loop structure to

an essential cycle of assessing, analyzing, and acting—has always been fundamental to effective task management. With the integration of advanced sensors, AI-driven analysis, networking protocols, automation, and robotics, we are enhancing this cycle to be more seamless and efficient than ever before.

Kubota, the Japanese equipment manufacturer, presented their view of the future with the Work Loop as a guiding principle.

offering more customer solutions across its entire equipment portfolio and providing greater choice—offering diverse powertrain options, seamless access to data and analytics, improved connectivity, and advanced automation. This approach ensures that Kubota meets increasing complexities and challenges with more certainty and simplicity and empowers its customers like never before.

- Smart Autonomous Sprayer – A fully autonomous chemical sprayer that scouts to identify pests and sprays with precision to lessen spray drift and overuse. The result reduces labor and the use of chemicals in the field.

- Flash – Ultra-detailed images are gathered to detect plant-level health. When coupled with AI, Flash provides recommendations on a grower dashboard to help make crop decisions one plant at a time.

- KATR – The Best of Innovation winner in the CES Innovation Awards 2025 program, the Industrial Equipment and Machinery product category, Kubota’s four-wheeled all terrain, multifunctional robot. The KATR maintains a level cargo deck when working on uneven terrain and can work autonomously or remotely to tackle a range of versatile applications in agriculture and construction environments.

Within the specialty crop space, harvesting is often one of the largest cost operations (could be up to 70% of the total cost), with weeding etc. coming up the second place. Automating harvesting (which is typically done by human labor) is an extremely difficult technical challenge, though companies have made progress. The next challenge is to make the economics work.

Companies have focused on automating weeding through different mechanisms like mechanical weeding, and laser weeding in the leafy green and other specialty crop space. A large hand crew is replaced by a single machine, equipped with cameras and edge compute AI models to identify and remove weeds in real time.

Even though we are no where close to Peter Zeihan’s vision, you can already see how different companies are advancing towards that vision with different pieces of the puzzle.

Key takeaways

- Business cases and economics have to work for automation and autonomy compared to existing solutions.

- Understanding which part of the “work loop” your automation addresses is important for adoption, pricing, and technology road-mapping.

- Even if the business case, and economics works, you still have to understand the risk appetite of your customer, when it comes to adoption. It will help you sequence your product roadmap, and go-to-market strategy.