Is Ozempic-as-a-Service a better option?

Decommodification through nutritional differences

It is Super Bowl Sunday here in the US, and as football fans gather to watch the big game around bowls of guacamole, chips, wings, and beer, it is important to reflect on nutrition and health.

Is Ozempic-as-a-Service a better option?

The company I worked for in the early 2010s was one of the earliest companies to provide item level traceability for a premium product like strawberries. Item level traceability is much more difficult and detailed than lot-level traceability, and it should only be applied where it makes sense in terms of the use case and the context.

In item-level traceability, each individual item or unit has a unique identifier, such as a serial number or a barcode/QR code that is specific to that single product. It is important in industries where safety, liability, and accuracy of records are paramount (e.g., medical devices, pharmaceuticals, high-value consumer electronics).

Our customer (a large strawberry grower) wanted to use item-level traceability to understand how supply chain and on-farm attributes impact the consumer experience with their product. Every clam shell of strawberries had a unique QR code, which was different from every other clam shell of strawberry grown, packaged, and shipped by them.

As a consumer, you could scan the QR code on the strawberry clam shell and answer a few questions about your experience with that clamshell of strawberries. Each survey was tied to the unique QR code for the strawberry clam shell.

Did you like the taste? Were they too sweet?

How did they look? Did they have any mold?

Did they survive in your refrigerator till you were ready to eat them?

On the back end, the unique QR code was tied to some critical information like - harvest date (when were the strawberries picked), variety of strawberries, farm and ranch where the strawberries were grown and harvested from, and some other attributes. All of the backend information was not visible to the consumer.

With a small incentive for the consumer, the strawberry grower was able to collect thousands of pieces of product performance feedback at the consumer level and link it back to farm and some supply chain attributes. The goal was to understand if we could uncover any supply chain or farm level attributes which had a statistically significant bearing on the consumer level performance of strawberries.

We often learnt surprising things that strawberries grown and harvested in California sometimes reached the east coast consumer faster than someone in Los Angeles, due to supply chain constraints! All else being equal (which was not easy to figure out), certain strawberry varieties lasted longer than other varieties etc.

It was extremely difficult to make claims with confidence as there was a large part of the supply chain which was not lit up with information as a clamshell of strawberries goes through multiple hops once it leaves the farm, with a large portion of its time spent in a wholesaler or grocery retailers distribution network across distribution centers, grocery stores etc.

The long term idea was to learn through this process, and then try to light up the middle of the supply chain to build confidence in some of the correlations, which could ultimately help with making different operational decisions across the supply chain.

The investment in a program like this is justified if you believe and hopefully show that the program gives you insights to provide a better quality product to your end consumer. The better quality product can bring brand loyalty, repeat and larger share of the wallet for the product category from consumers, and better supply chain performance from your ecosystem partners.

Decommodification based on nutrition

Can this be done in products like grain, dairy, meat, and poultry, and can it be tied back to what happens at the production level on the ranch or the farm?

Startup Edacious thinks so. They recently raised a seed round.

(Disclaimer: I am NOT an investor and DO NOT have any other financial interest in the company).

Our mission is to build a food system that improves human and planetary health.

We do this through the development of technology that makes nutrition the foundation of decision making in every step of the supply chain, from production to consumption, from soils to our tables.

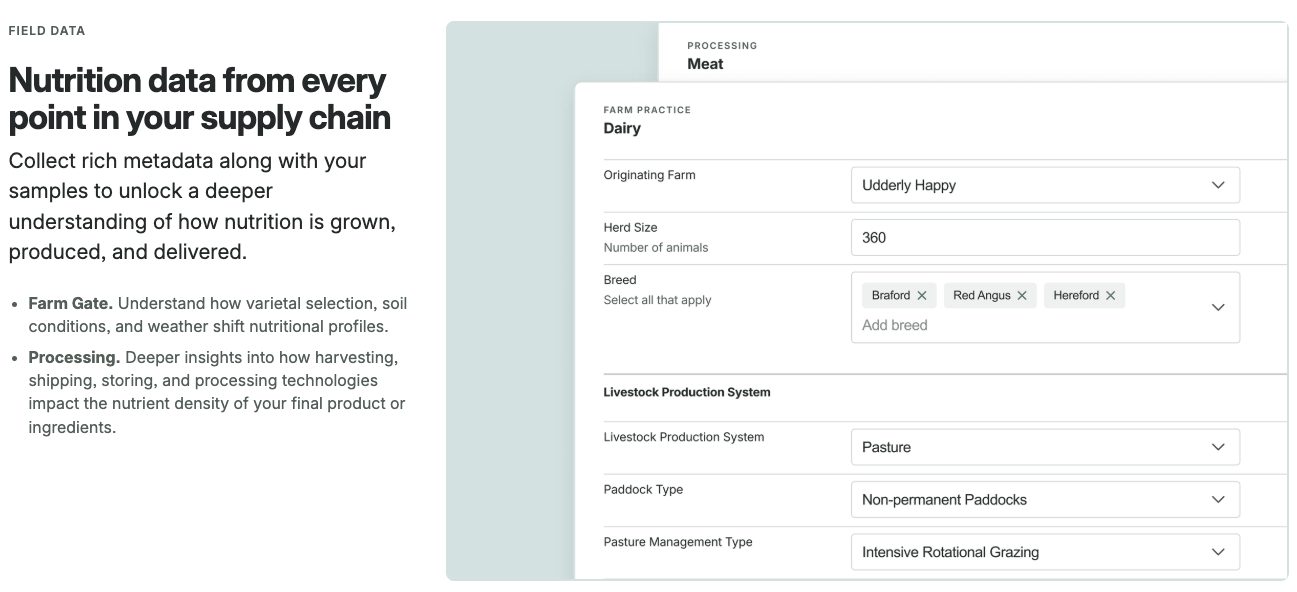

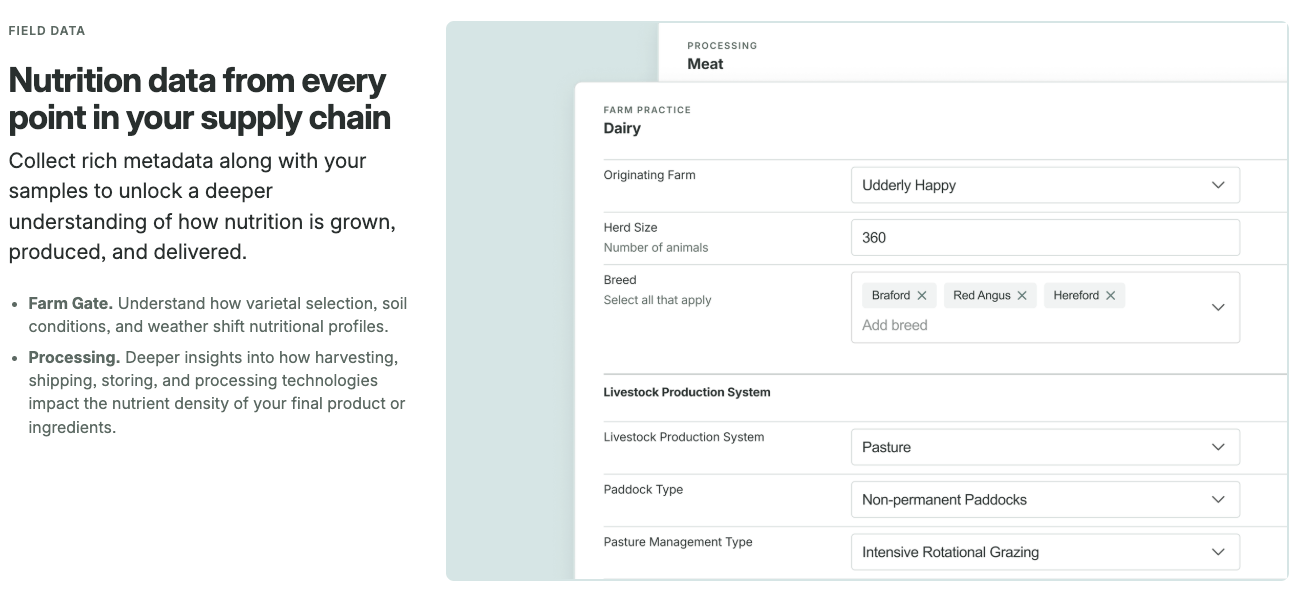

As a first step, Edacious is developing high-throughput lab testing capabilities to conduct nutrient analyses on grains, milk, meat and other whole foods. Nutrient analysis is critical for all consumer packaged foods due to regulatory requirements on food labels, and to help consumers make informed choices. Edacious is collecting data on 40-50 attributes relating to how the food is produced.

Their goal is to provide nutritional transparency around nutrient density. According to Pete Oberle, managing partner, Trailhead Capital, and an investor,

Nutrient density should be the catalyst for full food and agriculture value chain transformation. Edacious is making that possible by measuring and mapping nutrient density 10 times faster and cheaper, with an intuitive interface that incentivizes and enables the best regenerative practices from producer to consumer

Edacious is able to dramatically reduce the cost of nutrient analysis by 10X (roughly $ 200 compared to $ 2500 in a traditional lab) and so it becomes feasible for food producers to do multiple samples at a lower cost.

Edacious has an interesting hypothesis, (highlights by me)

Farmers have been incentivized to prioritize yield above all else, which has led to declining food quality, environmental degradation, poor nutrition, and the commoditization of food. By demonstrating that different farming practices and inputs can deliver meaningful improvements in nutrition that may command a price premium, Edacious hopes to provide a different incentive structure.

We started to see research showing that healthier soils developed through regenerative agriculture practices, change the nutritional quality of the food, which we felt could unlock a major market mechanism to incentivize better, healthier soils through the differentiation of food quality.

We’re really focusing on where things are commoditized, on animal products, grains, and fresh produce where there’s a lack of brands and differentiation, where better data and insights can transform those markets.

Screenshot from Edacious Website

Two hairy questions

For the current discussion, the two biggest questions in this are:

- Can the nutritional differences be attributed to a difference in an input variable?

- Will downstream buyers value the nutrition differences and are they willing to pay for it?

As per Edacious’ hypothesis, they want to decommoditize products like animal products, grains, and fresh produce, which have limited brands and product differentiation.

Commodity products like grains, and fresh produce are used as inputs into other products. The nutritional differences matter much more in the packaged version of the food, and many of them come from processing rather than the commodity product. For example, white brand and brown bread have different nutritional profiles and consumer segments, but most of the differences are due to how wheat is processes rather than the type of wheat used.

In the latest edition of Prime Future, Janette Barnard talks about a similar problem but in a slightly different context of yield equations in meat processing. (The Yield Grade algorithm) (highlights by me)

Interestingly, the Yield Grade algorithm dilemma is a perfect microcosm of many opportunities in agriculture: the intersection of more precise technology for higher quality inputs into an algorithm and more precise incentives to monetize the outputs.

It’s where the ability to capture sufficiently precise data meets the ability to incentivize the right players in the right way in order to encourage the right behavioral changes — resulting in better outcomes for everyone.

Edacious has to be able to solve these two problems, which other companies have struggled to solve in the past. For example, in edition 205 of Prime Future, Janette Barnard talked about 23andMe, a company which has struggled mightily to survive.

The root causes of their struggles were limited clinical utility of the reports as many conditions are influenced by multiple factors, not just genetics, and lack of incentives for the healthcare system (doctors, hospitals etc.) to care about the results. (You should go ahead and subscribe to Janette’s newsletter first)

The path to solving the hairy questions

What is required to make this happen?

- Low cost nutritional testing of whole products, for the right set of nutritional attributes to help collect a large corpus of data.

- Understanding of supply chain operational constraints, which could have any potential impact on the nutritional profile of the product. This is especially true for fresh produce, as the nutritional profile is just one element of the end consumer experience, as I talked about through the strawberry example. If you are talking about fruit and vegetables used for consumer goods like juices, salads, etc. processing elements like texture, oil content, viscosity etc. are much more important than just nutrition.

- Understanding of on-farm operational activities and management practices (how much and which fertilizer was applied, what was the nutritional profile of the feed given to animals for meat or milk production etc), environmental conditions like weather and soil characteristics, and genetics used to grow those crops.

- Statistically significant differences between input and output variables (nutritional and processing attributes - for example, nutrition of grain is not the only important factor in the food production of say a cereal bar, there are issues around taste, texture, manufacturing costs, production constraints etc.).

- Ability to attribute the difference in nutritional value to some different action upstream. (for example, different genetics, or management practice, or processing step)

- Ability of the ecosystem participant to execute a different action to get a chance at a nutritional profile and this change should be economically viable for them. For example, let us say wheat has a certain nutritional profile when it is grown a certain way, which is not economically feasible for the farmer, compared to their existing methods. This change will not happen at the farmer level, unless it is economically better for the farmer.

- Ability to communicate the difference in nutritional value to downstream buyers.

- Economic value for the downstream consumer or food processor or CPG company about the nutritional profile differences.

- Ability to share any incremental value created across different participants within the ecosystem.

Farm management systems have struggled to decompose yield drivers in commodity row crops, because it is extremely difficult to do. Even if you can do it it is difficult to attribute the increase in yield to precise recommendations made by your data driven software. This is one of the main reasons why Farm Management Software has had adoption problems and has struggled to make money on its okay.

Edacious is not blind to these challenges and seems to accept that it will be too difficult to answer the question of whether nutritional density and nutritional differences can be attributed to specific farming systems due to the large amount of variability within and between each of these systems. This is even before we have solved the incentive problem. (highlights by me)

Edacious is not, however, making “sweeping generalizations” about specific farming systems when it comes to nutritional density, however. “That’s never going to work,” said Smith. “There’s just too much variability within and between each of these systems.”

I hope the “Food for Health” crowd does not push for incentives for farmers to grow more “nutritious food” for better health outcomes downstream to add on to the ethanol and sustainable aviation fuel incentives.

If they want the government to spend money on better health outcomes, I would rather the government provide free or subsidized Ozempic-as-a-Service to everyone, with a basket of fruits, vegetables, and favorite proteins as an add on.

What do you think?