Let a thousand robots actuate

Robotic startups bloom

If you have been following this newsletter, you know I am a big fan of infrastructure.

I love to talk about tools which can be used by application builders.

I love to talk about the possibility of unleashing creativity to build solutions using those tools.

I love to talk about how the right tools and infrastructure can let a thousand flowers bloom!

As a follow up to the recently concluded FIRA Ag robotics event, Walt Duflock wrote about the increase in standardization in specialty crop automation and how it is good news for the industry.

Walt Duflock provides real numbers around robotic product development, but the main thrust of the article is about building standard tools and building blocks, which can be reused by innovators. The “lego blocks” (as Walt calls them) are either commoditized, open sourced, or available at a lower cost due to repeated use.

The cost for an AgTech startup to build their initial product and get it into market are among the highest for any tech segment, and can frequently run $50–100M to get a 1.0 product completed and into market with partners or direct sales teams that can sell and support them so they can get to global scale. Roughly 2/3 of the eventual number is the initial product effort, including both early R&D and Product Development, and the other 1/3 is spent on getting the product into market and into customer fields, often in multiple markets (a requirement because many growers need multiple growing regions to support 12-month product availability).

Given that, the more that can be done to reduce the capital and time required for AgTech startups to get to a 1.0 version of their product, the higher their chances of success. Western Growers is working with multiple partners on a tech stack that can help by producing a set of reusable “Lego style” components that can be re-used by all AgTech innovators (big and small). This will help with reusable image libraries and other key components that are important requirements but are not huge competitive differentiators. This means they can be commoditized and startups can focus on the key areas where there is intellectual property (IP) to be protected and valuation to be captured by the startup.

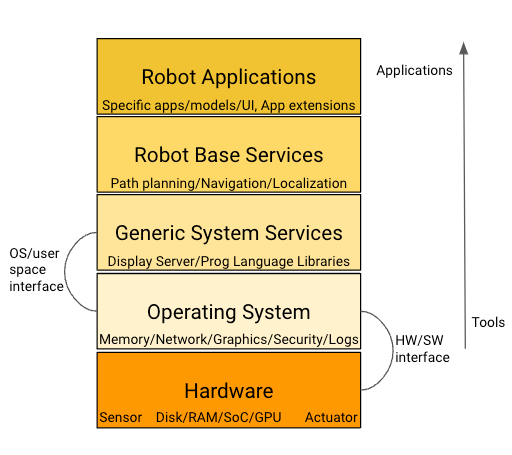

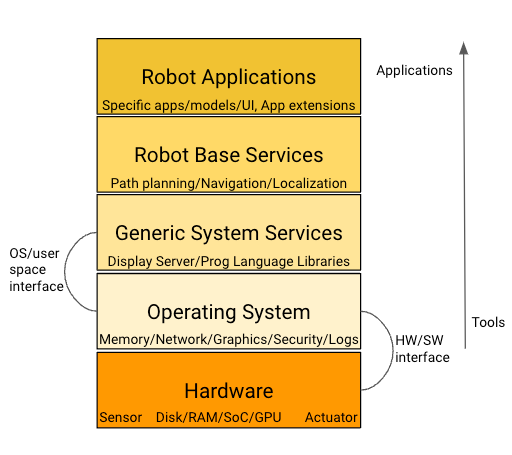

Robot platforms provide generic robotic capabilities for hardware and software, without building application specific capabilities. Building robot platforms is equally hard, as your customer is not the end user of a particular application but the application developer for that application.

Platforms are incredibly powerful as they provide the tools (or lego blocks to use Walt’s language) to rapidly build other applications. Imagine how difficult (and inefficient) it would be, if to make accounting software, you had to design and build computer hardware, and an operating system to run on the hardware, before you got to building your accounting software.

The first robot specific layer is the robot base libraries & services layer, as it contains functionality independent from concrete robot applications. It provides generic capabilities like path planning, navigation, and localization.

The top most layer is the most application specific. This is the layer that defines what the robot is actually doing, i.e. picking a strawberry or an apple.

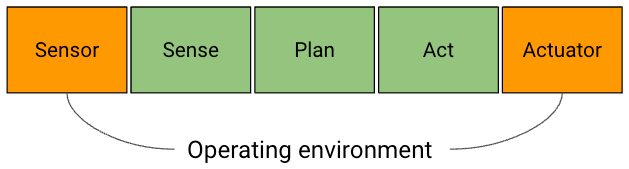

The sensor and the actuator are the hardware components of the robot, For reference, a sensor could be a camera or a vision system (in the strawberry and apple examples above). The actuator is the hardware component performing an action (in the strawberry example, it is the robotic arm with scissors to cut the stem of the strawberry).

Walt’s article talks about 3 straightforward enhancements, which has led to standardization and creation of tools (or lego blocks) which can make it faster and more efficient to build specific end user applications like strawberry or apple picking.

- Standardized OS (operating system) options for AgTech startups

- Standard implement format for the equipment

- Standard image libraries

I do agree with number 1 and number 3 on the list above.

The number 2 (stand implement format for the equipment) is described as,

Startups like Verdant Robotics and Stout AgTech have from launch through development focused on a “back of the tractor” implement format which allows them to leverage tractors that almost all farmers have so they can focus on just developing the machine that does the task.

For example, if you want to design and sell technology to carry some stuff while riding a bicycle, you will not design a brand new bicycle, but design a bicycle carrier.

RIght now, the “back of the tractor” does not feel like standardization, but a way to leverage the existing install base of agriculture equipment already out on farms. It is a way to reduce your development costs, and your go-to-market costs, and push for faster adoption of the technology.

The refresh cycles for farm equipment are long (5-10 years at a minimum) and so it is much harder to sell new robotic equipment which is standalone, and has to be purchased new vs. selling a “back of the tractor” attachment.

A back of the tractor attachment will be much cheaper to build, deploy, and support for the attachment provider. Similarly for the grower or the operator, the back of the tractor can be adopted sooner, and requires a smaller financial outlay.

There are many interesting developments in building the tools and infrastructure in agriculture robotics, which should create new robotic applications within agriculture, whether it is specialty or commodity row crops.