Second order effects

Will autonomy lead to more than removing a human from the equipment?

Second Order effects

In “Breaking Bad” the main protagonist and high school chemistry teacher Walter White starts cooking meth to pay for his cancer treatment. He ends up being the Pablo Escobar of the South-West United States.

The adoption of the automobile in the US and the highway system improved personal mobility significantly. It led to suburban sprawl, commuting culture, and morning and evening radio shows. For example, between 1950 and 1990, the aggregate population of central cities in the U.S. declined by an estimated 16-17%, even as the national population grew significantly.

Research by economists like Nathaniel Baum-Snow (Did Highways Cause Suburbanization? )suggests that without the interstate highway system, central city populations might have actually grown by approximately 6-8% during that period.

Image source: Did Highways Cause Suburbanization?

Other recent examples are a decrease in DUI incidents due to the introduction of ride sharing services like Uber and Lyft .

We often see this with new technology. Beyond the primary effects of the technology (for example, personal mobility), it can often lead to much larger and unanticipated second order effects in other sectors of the economy and human life.

With the improvement in computer vision, sensing technology, and edge computing, we are seeing more and more automation (“Augmentation is on the road to Automation”, SFTW, Sep 18, 2023) and autonomy coming within agriculture.

The first order effects of reduction in reliance on operator labor is obvious. But what are and could be the potential second order effects of autonomy within agriculture?

Autonomy in agriculture equipment

The US agricultural workforce has been shrinking for many years. The agricultural workforce is actually shrinking all over the world with a few temporary anomalies.

During the same time, yields have increased, while the amount of arable land has not changed much except in the Global South.

Yields have gone up significantly due to a combination of better genetics, improved management practices, and better information technology over the last 50 years.

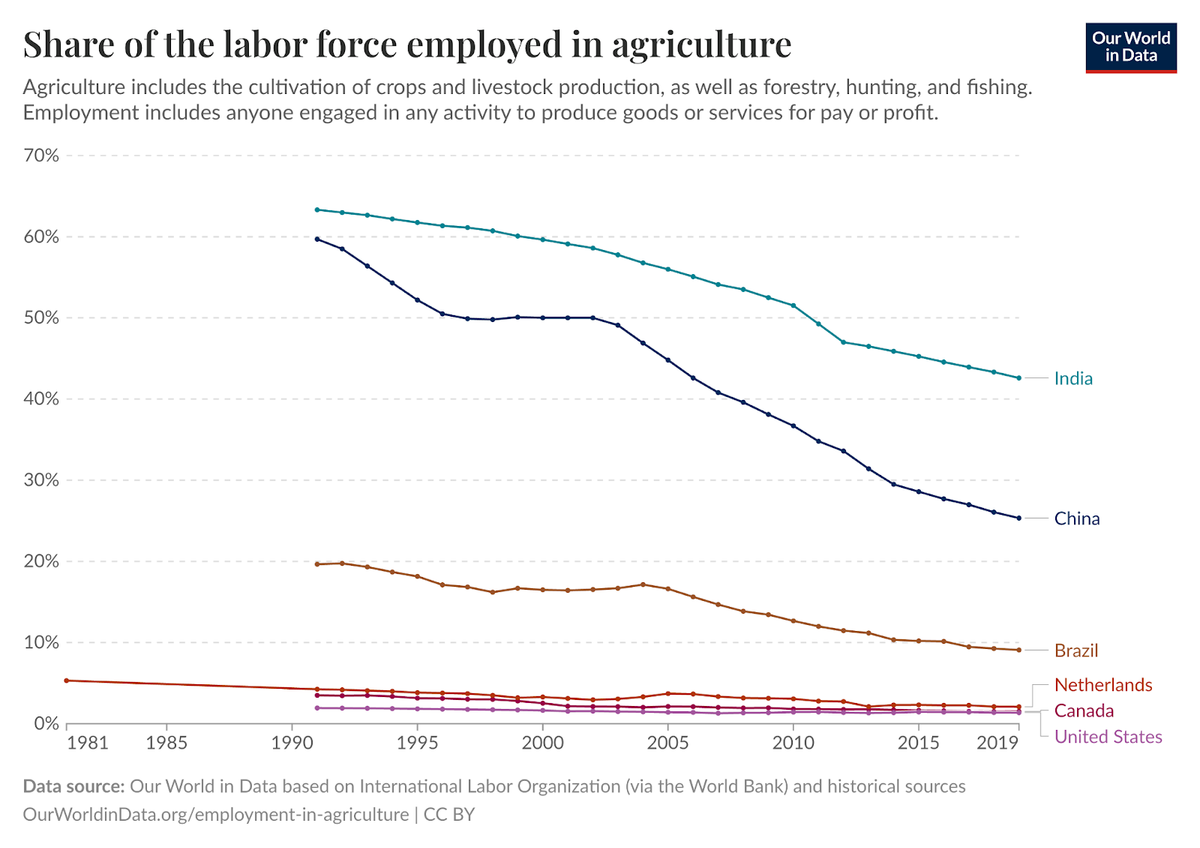

The increasing yields on a per unit area basis are accompanied with reduction in the percentage of population involved in agriculture with dramatic falls in India, China, and Brazil. Overall, this is a very good development, as it means fewer people are able to produce more food.

If we assume a constant amount of farmland, a decreasing number of farm workers requires an increase in productivity per farm worker. Even though productivity has gone up, there is still a shortage of workers for farm operations.

Within the commodity row crop space in the US (and even in places like Canada, South America, and Europe), productivity has been scaled by scaling mechanization with bigger and faster equipment.

For example, a typical self-propelled combine harvester in 1978 was rated at 170hp and could harvest 3 acres per hour of typical wheat at the time. Today, a John Deere X9 1100 combine is rated at 690hp and can combine 30 acres per hour in today’s higher yielding wheat compared to 1978. (Historic Agriculture Equipment Reports)

Combine harvesters have seen dramatic improvements in both their processing power (engine horsepower) and their capacity to harvest crops, measured in acres per hour or per day.

We have seen a similar increase in planter capacity with most of the capacity increase coming through wide planters, going from 6-row planters (15 ft wide) which can cover about 8 acres per hour to 36 row planters (90 ft wide)which can cover about 46 acres per hour.

Though we are seeing the limits to this strategy, scaling alone is not sufficient due to operational, and financial challenges. Large equipment has challenges with transportation, financing, resale value (more on this later), storage, are single points of failure, and cause soil compaction. (See also, “Is bigger machinery always better?” Successful Farming, Feb 2025)

More importantly, large and expensive equipment does not meet the needs of smaller and medium sized farmers. They are often left behind when it comes to adoption of technology.

For example, in the McKinsey study from 2023, "Agtech: Breaking down the farmer adoption dilemma"

Across all markets, large farms—more than 5,000 acres—are the most willing to adopt AgTech solutions (81%), with 76% of medium farms (2,000 to 5,000 acres) and 36% of small farms (fewer than 2,000 acres) using or planning to use at least one technology in the next two years.

We see the same effect happening for precision agriculture-hardware adoption across the globe, with Asia lagging in adoption at just 4%.

Image source: McKinsey study from 2023, "Agtech: Breaking down the farmer adoption dilemma"

There is another interesting effect happening from a financial point of view, which is related to farm consolidation and associated resale value of expensive equipment for 2nd and 3rd buyers.

Resale value of large equipment

According to USDA data, 4.4% of large farms account for 47.6% of production in the US, and 13.9% of the largest farms account for 82.9% of production.

Due to farm consolidation, the farms buying new combines are very big. The gap between the 1st and 2nd buyer is expanding, and the 3rd buyer is way smaller compared to the 2nd buyer. The consolidation at the top requires a certain value of the equipment and necessary depreciation for the combine to be affordable to the second buyer.

Image source: Farming and Farm Income, USDA ERS

A $1.1M combine now has to absorb more depreciation than in the past. If the farmer buying this combine expects it to be worth 70% of retail price after 3 years, they have to utilize $330,000 over 3 years or $110,000 per year. If they use the combine at its rated capacity, they might harvest 5,000 acres with that single combine which means it costs $22/acre for that period of time.

Image source: John Deere X9 1100 combine for sale on All Machines

There is currently a weakness in the resale market. If that combine drops its value by $200,000 and now only sells for $570,000 instead of $770,000 it means the farmer has to add back $13/acre of additional cost. Instead of a cost of $22/acre it is now $35/acre. In many cases, it is their margin. In 2025 with corn prices at $4.75/bushel that is now costing 3 bushels per acre more than planned.

The concentration at the top combined with expensive and powerful equipment created by the Deeres of the world have created a weak resale market. The new buyer will have lower confidence in resale and will delay buying the equipment.

The tight coupling between the equipment and the human driver, combined with the consolidation of farms have resulted in larger and faster and more expensive agriculture equipment over the years.

Autonomy is about to break that paradigm.

Autonomy removes the operator from the tractor

Driverless systems help mitigate labor shortages by enabling farmers to reassign staff to other activities, and improve the equipment-to-worker ratios.

Autonomy tackles the challenge of finding operators for farm equipment, especially in the global north where only 1-5% of the population is in farming. Young people (if opportunities are available) want to move to the cities, and so it is a skill gap as well.

Autonomy addresses issues like human operator tiredness, and long working hours. Climate change is increasing the uncertainty of optimal operational windows, and autonomy is a great way to increase your chances of hitting those uncertain windows quickly and with confidence. (UIUC study from 2019).

But most importantly:

This is a profound change which could have far reaching effects.

One of the key drivers for scaling by making larger and faster equipment was this unique connection between the operator and the equipment. If the number of people working in agriculture is shrinking, and if a human operator can work only a certain number of hours in a given day, then it makes sense to try to cover as much ground as possible when the operator is in the equipment.

This unbreakable tie between the operator and equipment leaves one with no other option but to build bigger and faster equipment. Once the equipment and operator are decoupled, the need to keep building bigger and faster equipment is no longer there.

Can this give rise to an orthogonal system for how farm equipment is developed, built, deployed, and used on a farm?

A future could have teams of autonomous equipment working in tandem from a remote control center (Graphic by Rhishi Pethe)

Paradigm shift with equipment size

If more and more farmers adopt autonomous equipment, will it lead to larger equipment and larger operations or will it lead to smaller equipment, as the equipment can now operate for longer times?

Instead of buying a million dollar piece of equipment which requires a driver, and causes resale value issues as seen above, would it be sufficient to buy 7 pieces of autonomous equipment which are smaller? What if they cost $ 100K each, and can do the same amount of work as a million dollar equipment with a driver, as they can work longer hours?

Doing more with less people does not have to mean bigger and faster equipment all the time in the future.

Could the second order effect of autonomy be smaller and smarter equipment? Could you do the same or more with a swarm of smaller equipment compared to one single piece of a massive expensive piece of equipment?

When you take away the operator, it is not too much of a stretch to imagine a world of a swarm of robots living in the field 24 x 7. Autonomous equipment in the field can take action as soon as they see something which they have been trained to recognize.

For example, noted political strategist, Peter Zeihan provides one view for the US Midwest.

He imagines a future in which automated equipment with cameras will take photos of each individual plant. The equipment will identify if the plant is a weed, or a crop and assess the health of the crop. It will give it a little jolt of whatever is appropriate (herbicide, pesticide, fertilizer, water etc.). He believes we are on the verge of production increasing by a factor of 2–3 (“on the verge of” is subjective!). It will turn conventional farming into conventional gardening, with a lower pollution rating and a far lower carbon footprint. (Highlights by me)

Second order effects on crop protection and fertilizer applications

This could have a profound impact on the types of farming practices which are used.

For example, it could lead to the development of different types of fertilizers or herbicides, which can be delivered in tiny but effective doses, at the right time, at the right place, and in the right quantity. One does not have the need of a heavy machine which goes to the field every month.

Given that the equipment could “live in the field” (if they are solar powered), it could detect issues and needs of plants very quickly through a combination of vision and other sensors on board. (Also see my SFTW Convo with Leo Carvalho, “Technology that lives in the field” Dec 2024) It could lead to a completely different set of agronomic management practices, instead of the “pass” driven mechanism which is practiced the world over.

It could lead to novel products with more targeted and efficient formulations of crop protection products, new adjuvants, more select herbicides, different potency levels than today, and reduced use of inputs like fertilizer and crop protection without sacrificing yields or quality, and new agronomy and farming practices, and different outcomes.

If the move towards smaller equipment happens, it will require people with different skill sets like operational management, systems and software engineers, and tight processes to run such an operation.

Second order effects on business model

Smaller, and modular equipment

With the issue of obsolescence, the mechanical aspects of equipment will probably last longer than the digital and electronic aspects of the equipment. It is not uncommon to see 40 year old equipment in agriculture.

For example, when I visited sweet potato farmers in Merced county in California, most of the sweet potato harvesters had been built in the 1980s.

Sweet potato mechanical harvester in Merced County, California (April 2025). The machine was built in the 1980s and since then has been modified. (Photo by Rhishi Pethe)

Modular designs help with the diversity of situations which one encounters in agriculture. One of the challenges with scaling agriculture innovation, is what works in a given context does not work in another context due to differences in crop type, soil type, weather, management practices etc. (“Agriculture Robotics is Difficult AF” - March 23, 2025)

Having a modular design for agriculture equipment is very useful to build a flexible and hence a scalable business.

You want a strawberry robot to go through fields with a 48 inch bed? Not a problem. You want the same robot to go through a field with a larger bed width? Just expand the robot and now it can work with a different bed width.

Modularity allows for addressing a larger set of use cases and so is critical to attract venture and other forms of investment. A VC is much more likely to invest in a robotics company which can work across multiple crop types, vs. just one crop type. We see a modular approach with companies like farm-ng, Burro etc

If a modular design can be paired with open source, then it could potentially be even more powerful, though open source software has many challenges within agriculture. (See my past posts from 2021 about open source in agriculture- 1 & 2)

There is a small but growing movement towards open source and modular designs for agriculture equipment. The work done by Guy Coleman for the OpenWeedLocator (OWL) is a great example of open source principles for commodity row crop agriculture.

Having access to low cost, highly customizable agricultural equipment that is also open-source technology has the potential to benefit millions of small and medium size farmers both in the developed as well as the developing world. Small and medium sized farmers typically do not have easy access to mechanization.

Retrofitting by design

Majors like Deere follow an Apple approach with high end hardware, and software under their brand. They service the high end large scale row crop farming in the developed world, and in places like Brazil.

Another variation for agriculture equipment could be an Android variation.

The hardware is inexpensive. The “smarts” of the equipment come through an operating system and applications. For example, you can buy a decent Android phone for less than $ 100, and it works quite well for billions of users.

Given the longer life of mechanical elements of ag equipment, it might be better to have loose coupling between the hardware and software. This can be managed through retrofit kits, which can be swapped out with updated capabilities without huge changes to the underlying hardware.

This can extend the life of hardware, without losing the ability to continue to add additional intelligence through a retrofit design. A modular design could even change some of the underlying hardware elements to improve the capabilities of the equipment after the initial purchase. There are many types of operations depending on crop type, and so there might be different hardware configurations.

This begs a question.

Could a Mahindra or a some South East Asian manufacturer provide hardware in large volumes at low cost? Can a strong software and technology provider provide an equipment operating system, with room for application developers?

Rental and lease market with power by time

Many commodity row crop farmers in the US own their planters for risk management as it is a critical activity. Farmers often own their own harvesters and combines, though there is a custom harvesting service business prevalent in the US. Farmers typically use their local ag retailer or co-op for spraying crop protection products.

One of the challenges with a rental business for large equipment is the logistics associated with transporting the rental equipment from one location to another. Transporting commodity row crop farm equipment (e.g., combines, tractors, planters, sprayers) by road in the U.S. is costly due to the size, weight, regulatory restrictions, and safety concerns associated with such machinery.

Depending on the size of the equipment being transported, you might have to take off the wheels, take off some other components like sprayer arms etc. You often need an escort vehicle for oversized equipment, your logistics provider needs to have special insurance etc.

Image source: JD Skiles company

Why do we have millions of dollars of equipment sitting in sheds for 10 months of the year? Autonomous equipment will be able to do what we do today with big hardware for a lower cost.

Instead, what if you could transport a piece of equipment which fits on a flat bed?

Depending on the size of the farm, one could rent a swarm of equipment. Given that you are using a fleet for the same operation, you don’t have to worry about single points of failure, you could respond more quickly, and could potentially make your farm more resilient, and efficient at a lower cost.

A rentable smaller piece of equipment could also address the needs of small to midsize farms, which are not very well served as the large farms. With a rentable piece of equipment, the risk of technology evolution and/or obsolescence is taken on by the entity renting you the equipment by time.

Farms of all sizes could move to this model fairly easily. In this case, the equipment dealers main revenue is the equipment rental and service. When the lease is done, the dealer can refurbish the equipment and sell with an extended warranty to the 2nd tier buyer.

This is not a brand new model as it is already available and known to growers within North America for custom harvesters, and it is seen in high end automobiles as well.

Conclusions

There is a dire need for automation and autonomy in agriculture, though the regulations in my state of California are not keeping up. More than 88,000 farming positions are expected to go unfilled every year through the next decade, according to the U.S. Bureau of Labor Statistics. Meanwhile, farmers aren’t getting any younger, with the average age now nearly 60 years old.

The regulation from almost 50 years ago does not allow for autonomous farm equipment, though we have Waymos zooming around in San Francisco. Even as late as 2022, California voted down the proposal to allow autonomous vehicles on farms. Regulation clearly needs to change to allow for autonomous farm equipment, especially in California.

There are many other issues which need to be explored and addressed (in future posts) around service availability, risk management, financial models around CapEx vs. Opex for farmers, and regulations.

Autonomy in farm equipment can drive significant second order changes due to the decoupling of the equipment operator from the farm. Much more thinking and experimentation needs to happen on the combination of small size equipment with autonomy and solar tied with a farming-as-a-service business model (explored in my SFTW Convo with Jehiel Oliver, CEO of Hello Tractor, July 2021)

Autonomy combined with a different business model has the potential to not only make mechanization and precision technology available to millions of farmers, but also to change how farming is practiced worldwide.